Our industrial packaging services are designed to bring more quality, innovation, digitalization, automation and sustainability to the pallet wrapping process.

To this end, we work in collaboration with local, national and European partners to generate technology that allows us to offer our customers improved services with more advanced stretch wrappers that use stretch films with superior performance and provide higher quality data.

In 2021, we conducted our first materiality study to design an ambitious Sustainability Master Plan, aligned with the priorities of our stakeholders, to guide us in leading the transition of the packaging sector to a more sustainable one (see Sustainability Report 2021).

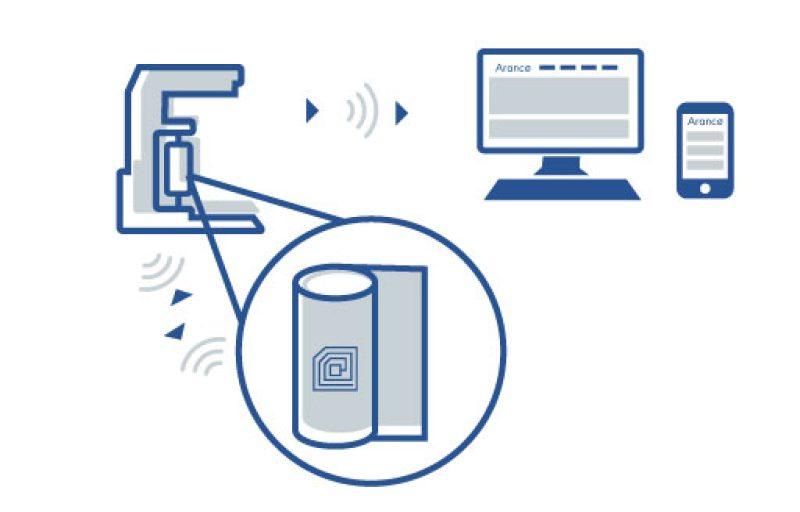

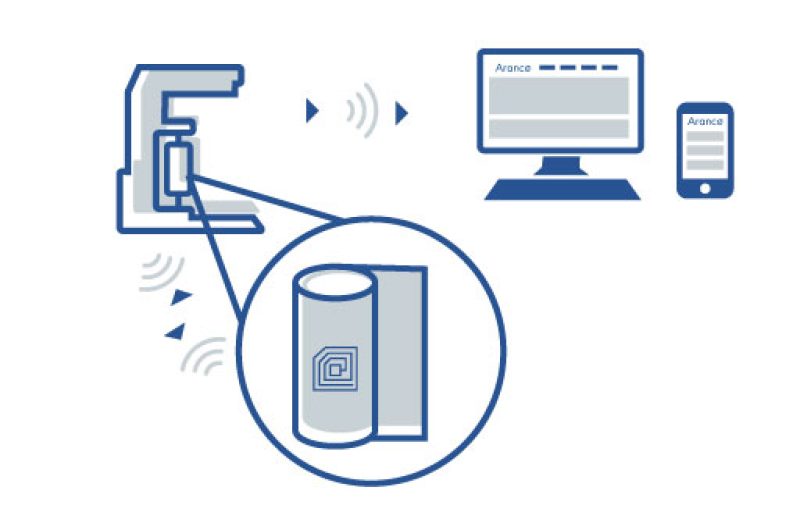

As a result of several years of innovation with technological partners and following this sustainability plan, in 2022 we began to develop the first Smart Films, stretch film rolls with RFID tags.

Smart Films, among many other advantages, will bring more efficiency and sustainability to our customers' baling process.

We are applying this technology as standard to the new range of smart wrappers designed and manufactured in 2022 (wrappers equipped with RFID reading devices), but thanks to our own technology, we will be able to apply it progressively to the wrapping machines currently in operation (more than 1,900 wrappers) installed at customers in Spain, Portugal and France.

Advantages of our stretch films with RFID tags

RFID technology applied to stretch wrappers and stretch film rolls will mean a giant leap in the pallet wrapping process, with enormous advantages for our customers:

Increased profitability:

- More and better information of the stretch wrapping process with accurate data: our customers will be able to know the cost of wrapping each pallet, as well as the number of meters of film applied and other essential process data.

- This set of new data will allow our customers to establish KPI's with which to measure the efficiency, profitability and productivity of their stretch wrapping processes and make better decisions to meet targets.

Increased productivity and sustainability:

- In multi-shift operations, our customers will have comparative data to measure the productivity and efficiency of each shift.

- With more data, the wrapping process will be more accurate and efficient, with film consumption adjusted to customers' needs, no unnecessary costs and less waste.

- RFID technology will increase communication and coordination between machines, consumables (film), devices and people.

Stock control and minimum stock:

- Updated data: our rolls and wrappers with RFID technology will allow our customers to know their stock of stretch film rolls through the Web Client, with access from any device.

- This technology will allow the system to automatically suggest to the customer the generation of purchase orders, which the customer will only have to validate.

Traceability:

- In the event of quality issues with any batch of film, RFID technology incorporated into each supply will provide detailed film manufacturing data from its origin.

An improved service at no cost:

- For our customers, the implementation of RFID technology in the stretch wrapping process will be at no additional cost to them.

Leading the industrial packaging industry's transition to sustainability

Since our inception, the concept of sustainability has been deeply rooted in our company.

It is essential for us to comply with and follow through on our Sustainability Master Plan and continue to make a positive impact on the environment by providing increasingly efficient and valuable services, building lasting and trusting relationships with our customers, employees and suppliers, and reducing our carbon footprint through optimization and automation.

In the coming months, we will present our Sustainability Report for the year 2022, which will compile all the commitments and actions we have undertaken during that period.

. Smart Films undoubtedly represent a further step towards sustainability in pallet wrapping and an important milestone in our plan.

Learn more about our sustainability strategy here: https://www.aranco.com/en/company/sustainability/

LEARN MORE ABOUT OUR STRETCH FILMS