In this new case study we talk about a Spanish textile company with a large international presence that started with a manual wrapping process with 17 micron stretch film, with many operators involved, numerous wastes and leftovers of unused film and recurring injuries and sick leave.

The company is committed to reducing film waste, reducing CO2 emissions and improving the ergonomics and safety of its warehouse workers.

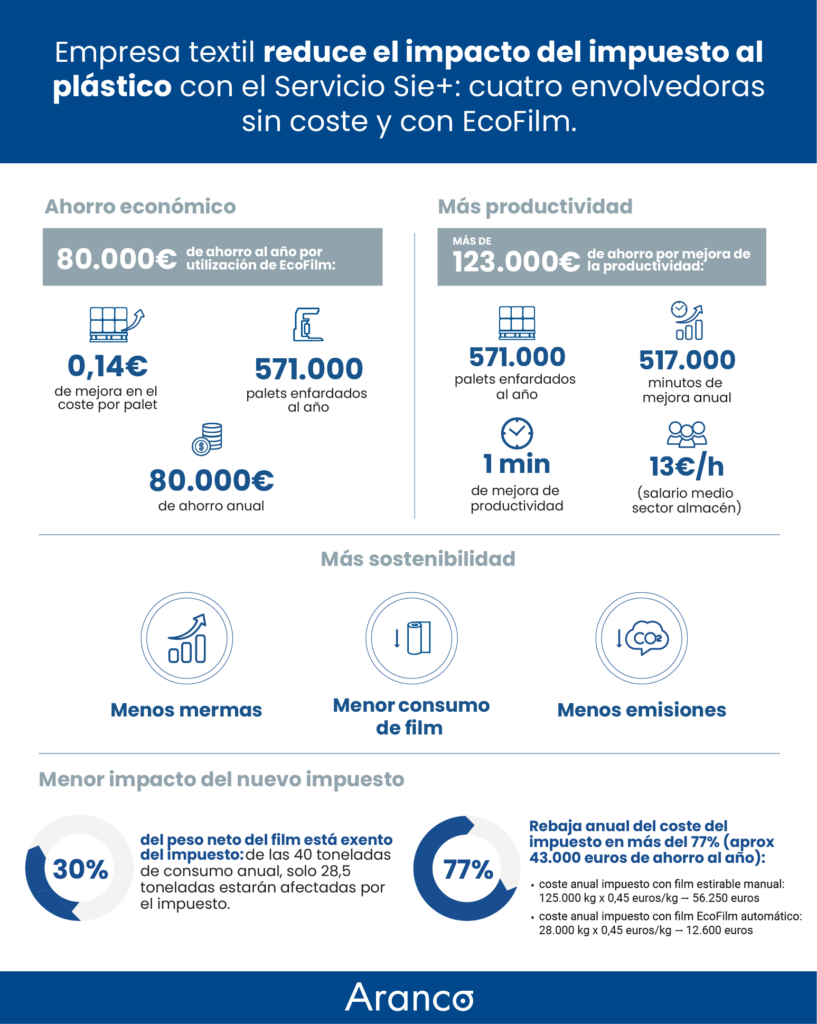

For this reason, thanks to our integrated Sie+ wrapping service, they have automated their wrapping process with 4 automatic wrapping machines at 0 cost, which has also improved the ergonomics and safety of their operators.

And, above all, they have achieved greater sustainability and great economic savings by reducing film consumption and waste generation and using a more sustainable film alternative: our Ecofilm, an automatic 7 micron high performance stretch film with 30% recycled content PCR (post consumer recycled).

-1980.png)